Abrasive Materials: Different Types of Abrasive Discs and What They’re Used For

Commercial and industrial sectors use many abrasive materials, in particular grinding discs. These discs contain several abrasive elements. Which can result in effective removal of material from the surfaces including hard-wearing materials. Such as cast, forged, various ferrous and non-ferrous metals & alloys. This is why abrasive discs are often important within foundries and similar production facilities. Of course, there are many different types of discs to choose from. Potential safety concerns such as the expulsion of larger debris may pose a hazard, without the presence of personal protective equipment. For the sake of this article, we will take a look at the discs that are used within foundries as well as some of their unique applications.

What is an Abrasive Grinding Disc?

The principle behind any grinding disc is simple. This type of abrasive product uses the power of rotation in order to slowly chip away at the surface of a substrate. Such as aluminium, steel or even titanium. Hand adjustment of the control mechanism is a much more flexible method when compared to other types of computer-controlled machining. These discs can be manufactured with a wide range of materials and fillers (this once again depends upon the intended application). Most importantly they will make quick work out of difficult to machine surfaces. Some of the most common abrasive materials which are used in the manufacture of grinding discs:

- Aluminium oxide

- Silicon carbide

- Ceramic / sol-gel

- Zirconia

Manufactured in various thicknesses and configurations, including bespoke sizing. Therefore they will accommodate even the most demanding of applications within industrial settings, including foundries and fabrication workshops.

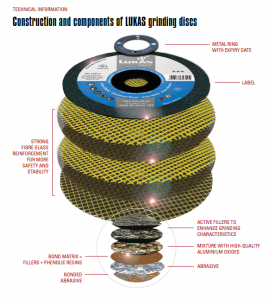

Below shows the construction of a conventional grinding disc:

The Benefits of Using an Abrasive Grinding Disc

The use of abrasive grinding discs offers many advantages. Whilst this method may not be as precise as other methods for example CNC machining above all it produces results much faster. To meet requirements refining or finishing of this product is possible.

Another interesting benefit is that to allow for mass production requirements, different metals can be ground. This can save time and a substantial amount of manpower. Many grinding discs are also cost-effective options when compared with other abrasive grinding methods. As these discs are attached to portable grinding machines, their sense of flexibility is nearly unparalleled within the metal fabrication sector.

The Primary Differences Between Discs

There are two types of configurations:

- Flat

- Concave/depressed

As you might have thought, flat discs can address flat or angular surfaces. Concave variants are highly beneficial when addressing hard-to-reach areas. Especially in the event that different amounts of pressure needs applying to achieve a specific finish. Engineering allows the possibility to create variations for instance to use in conjunction with many different abrasive materials.

The Types of Grinding Discs Available from Kayson Green

The team at Kayson Green offer a wide range of grinding discs. These include:

- Concave and flat

- 100mm to 230mm Ø

- Various abrasive materials including aluminium oxide, silicon carbide, zirconia and ceramic

- INOX and CAST specific qualities

Please take a look at this category in more detail in order to learn about the options available for your application.

Kayson Green specialises in providing quality grinding discs and other abrasive materials to a growing number of industrial sectors. Furthermore, we also offer additional products and services. Please get in touch with us to learn more. A representative will be happy to answer any other questions that you may have.

Other related abrasive products that may be of interest:

Mounted Points & Nut-Inserted Cones

Flexible Grinding & Polishing

Tungsten Carbide Burrs & Milling

Resin Bonded Fettling Wheels

Contact Us Call +44 (0)1206 751500 Email sales@kaysongreen.co.uk