Micro Lapping Film UK – Discover the Kayson Green Product Range

Micro lapping film is an ultra fine and precision-coated abrasive consumable for producing a super fine, highly consistent finish, when used along side other media, such as honing & superfinishing stones. As lapping film products are part of a highly specialised range, with several minerals and grit sizes for different specific applications, we dedicate this article to study these features in more details.

FEATURES, SERIES AND GRITS

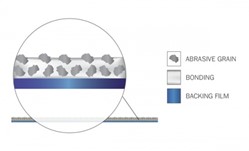

The slurry coating grit deposition is surely the most relevant and characterizing common feature when it comes to lapping film. The slurry coating technology, compared with the traditional electrostatic coating of microfinishing film, follows a very unique principle: the microabrasive grains are mixed together with resin bond and then coated in a one step process on to a PET backing film.

Another common feature of all fine lapping film is the clean room manufacturing environment. This avoids any possible contamination from external elements. The coating process in a clean room is fundamental to achieve a super consistent finishing process with the highest quality standard.

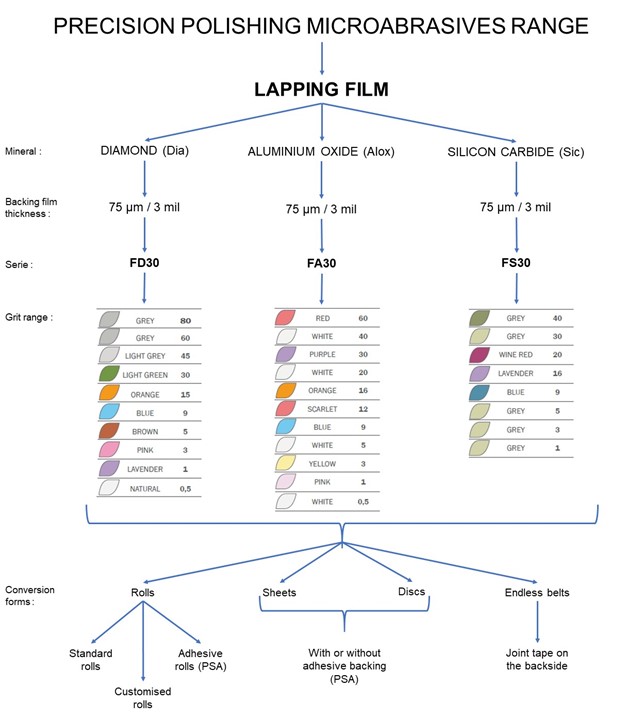

Lapping film differentiation between various grit sizes is made by colour coding. In fact, there is no printing on the underside because the increase in thickness from the layer of ink would strongly influence the consistency of the finish.

The schematic detailed below summarises the main features of the standard lapping film series available within the Kayson Green portfolio:

Lapping film products are used for very fine and soft applications. Because of this, the PET backing film is thinner compared with standard microfinishing Film: 75 µm (3mil) vs. 125 µm (5mil).

Moreover, the backside of the film is without an anti-slip coating which is not required for technical reasons.

In addition to the standard 3 main series detailed above, the following products are available on request:

- FI30 / FI31 / FI32 Silica Oxide Lapping Film: Dedicated to the final polishing of ceramic ferrule. Available ex-stock as 127mm/5” discs.

- FF30 Iron Oxide Lapping Film.

- FR30 Chromium Oxide Lapping Film.

On request, other products with thinner PET film of less than 75µm/3mil are also available e.g. 25µm/1mil and 50µm/2mil in specific grit types and mesh sizes.

Micro Lapping Film CONVERSION FORM OPTIONS:

Like every microabrasive film in our product range, lapping films are converted into several product types such as:

- Rolls

- Discs and sheets

- Endless belts

Thanks to the integrated and efficient conversion process, Kayson Green offers a fast and flexible service both on standard and customised items.

Let’s look at some examples of our product range:

Rolls:

We offer a wide variety of customized options in order to provide the end-user with best solution.

- Widths: From min. of 5mm to max. jumbo roll width.

- Lengths: From min. of 1mt to max. 300mt.

- Inner cores options: 26mm i.d. plastic core, no core (hole 32mm i.d.), 76mm i.d., 76mm i.d. with 4 keys.

- Winding direction: ASO (Abrasive Side Out) or ASI (Abrasive Side In).

- Diamond rolls come with an uncoated length of plastic film at the start/finish of the roll in order not to waste expensive abrasive material when a new roll is mounted.

- Back side: plain or adhesive (PSA)

Discs and Sheets:

- Available without (PET) or with adhesive (PSA) backing.

- Disc standard diameters are: 200mm, 203mm, 230mm, 250mm, 254mm, 300mm and 305mm. Other diameters are available on request, up to a maximum diameter of 350mm. Larger diameters may also be accommodated.

- Sheets PET max. width is the jumbo width and max. length is 1mt.

- Sheets PSA max. width is 350mm and max. length is 1mt.

- Diamond sheets and discs in grits 45 µm, 60 µm and 80 µm are available up to a max. width/diameter of 230mm.

Endless Belts:

- Width: Min. 10mm and max. the jumbo width.

- Length: Min. 320mm and max. None.

- Jointing tape positioned only on the backing

If you wish to obtain more detailed information regarding microabrasive film conversion processes, or would like to speak to an expert about what options are available to suit your exact requirements, please don’t hesitate to get in touch the Kayson Green team today.

View Products Call +44 (0)1206 751500 Email sales@kaysongreen.co.uk